Founded in 1982, Guangdong Yongquan Valve Technology Co., Ltd. is headquartered in Foshan City, Guangdong Province. It is a leading valve manufacturer in China. Its products are mainly used in municipal water supply and drainage, building water supply and drainage, fire water supply, air conditioning pipe network, industrial water, In the fields of seawater cooling, water supply and irrigation.

The company has more than 30 series of products and more than 5,000 specifications. He has obtained more than 50 national patents, and has edited and edited more than 30 national and industry standards. He has always been in the domestic leading position in technology.

The company's products are sold all over the country and exported to overseas. At present, the products have served more than 400 large and medium-sized water companies, more than 100 national key projects, and more than 20 overseas engineering projects. The products are widely used not only in major domestic engineering projects such as the Bird's Nest, the Water Cube, and the National Grand Theatre, but also exported to the United States, Canada, Russia and other developed countries in Europe and America.

We have always been committed to technological innovation, to lead the constant change of China's valve industry, to promote China's valves to the world, and to develop, manufacture and sell high-quality products that meet customer needs. Yongquan will ensure the long-term sustainable development of the company based on the multi-regional business model of localization and globalization.

Be the pioneer of the industry and build the first brand of Chinese valves

.jpg)

Since its establishment more than 30 years ago, Guangdong Yongquan Valve Technology Co., Ltd. has been focusing on the research and development and manufacture of valve products. It has made many breakthroughs in valve technology, creating a number of world-class products and laying the foundation for Yongquan in the field of valves. Core competitiveness. Mr. Chen Jianming, the president of the company, is a self-taught valve expert and valve inventor. He has always had a strong interest and enthusiasm for new products and new technologies, and this has shaped Yongquan’s long-term business strategy of focusing on technology research and development. company culture.

Bringing together the talents of the Quartet and leading the valve technology

The Yongquan R&D Center consists of technical experts with extensive product development experience. The company is committed to the research of the latest technology in the field of valves, and constantly carries out technical exchanges with world-class enterprises, and cooperates with major universities and research institutions in China. In 2013, he began in-depth technical cooperation with Ph.D. students in solid mechanics and fluid mechanics at Tsinghua University, and conducted in-depth research on valve structure, mechanical properties, and head loss.

Leaders at all levels are caring and encouraging us to achieve great future

Since its establishment, Guangdong Yongquan Valve Technology Co., Ltd. has always been highly valued and cared by the leaders of the Central and Provincial Committees. The leaders of the Ministry of Housing and Urban-Rural Development and the China Urban Water Supply Association have visited the factory many times to inspect and guide the work. They have affirmed the development of the company and encouraged us not only to stand on China but also to go global. The high evaluation and ardent expectations of the leaders have strengthened the ambition of Yongquan to build a national brand. Yongquan will hold high the responsibility banner, commit to improve the quality and image of Chinese valves, actively undertake corporate responsibility and social responsibility, and realize the long-term development of the company.

Advanced electrostatic thermal spraying technology

.jpg)

Yongquan valve adopts electrostatic thermal spraying process and automatic running water. The castings are preheated evenly before spraying, and fully cured after spraying, and tested by impact test, hardness test and voltage breakdown of the test piece to ensure the coating effect.

The thermal spray epoxy powder is environmentally friendly and non-toxic and has passed NSF certification.

Exquisite casting process and mold processing

Each Yongquan valve is precisely shaped by resin sand. The company adopts digital medium frequency electric furnace smelting technology and selects high quality and clean furnace materials for quantitative smelting. The hot metal of each furnace is monitored by a thermal analyzer in real time, and the effective content of elements such as C and Si is dynamically adjusted to ensure the expected chemical composition. Advanced physical and chemical analysis and metallographic testing are the best guarantees for excellent materials.

Technical exchange with foreign companies

Yongquan & Valve has always maintained technical cooperation and exchanges with many well-known international valve companies, and maintained a world leading position in valve manufacturing concepts and processing technologies.

Each Yongquan valve is unique in its ability to maintain its leading position in similar functions in terms of function and structure, appearance and practicality, leading the development of the valve industry.

High quality and perfect management mode

The company insists that every process is strictly controlled, and each part is repeatedly tested and inspected to ensure that the best quality and satisfactory products and services are brought to the user. Use our actions to retain each user's confidence in Yongquan.

Professional maintenance team, efficient and reliable after-sales service

Yongquan Valve has a professional maintenance team, and all the information of each inspection, maintenance and debugging is recorded into the database system in real time to ensure the quality and satisfaction of future service and tracking.

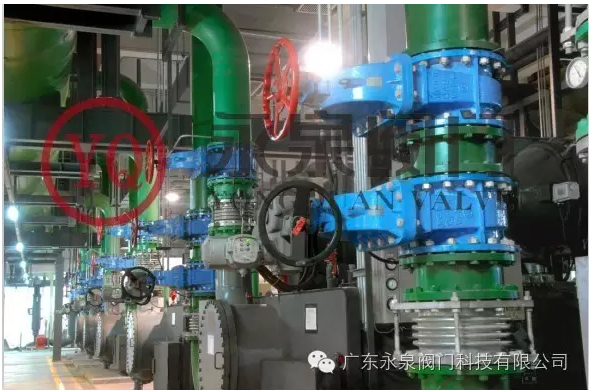

Product display

Backflow preventer

Drain valve

Butterfly valve

Butterfly valve

gate

Pump control valve

Fire gate valve

Energy-saving piston pump control valve

Vent